Unlike most of the projects I’ve done in the past, this one is going to be a multi-poster. There’s just too many ins, too many outs. What’s the project? Turn a toaster oven into a high-quality barbecue smoke generator. Aaaaaand go!

First of All, Why Bother?

I’ll concede there’s a certain Zen-like satisfaction that comes from using only fire. Constantly tending and tweaking, making sure everything’s right. I’ve done that, and with some success. what I want now though, is consistency. I want to start the process knowing there aren’t going to be any headaches. I want automation. It’s a travesty I know, but I’ve come to terms with that.

Design Criteria

Here’s what I’m going for. If I can get the smoker generator to do the following, I’ll consider the project a complete success. It should:

- Operate Unattended for 8-16 hours.

- Generate consistent smoke.

- Allow for adjustable smoke density

- Accept standard wood. (No custom bricks, no sawdust, etc…)

Easy right?

The Plan

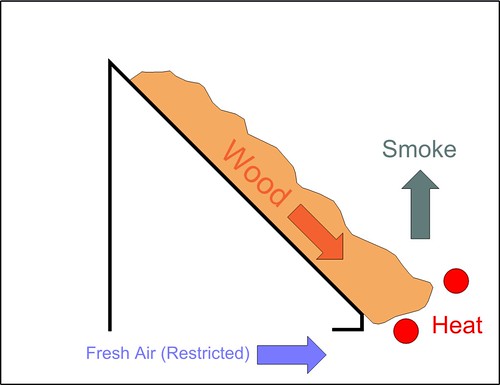

The design I’m going to try is pretty similar to what you’d see in a commercial smoker. The wood is on a ramp that leads to a heating element. A restricted amount of air is allowed to flow past the wood. Because there’s incomplete combustion, lots of smoke is generated. As wood is consumed, ash falls away and new wood takes its place. Gravity may be all I need for that to occur, but I’m guessing I’ll need to vibrate the ramp.

Stay Tuned…

It’ll be interesting to see how it goes. Subsequent posts will detail the construction process, as well as testing and any re-design. If it all fails in a huge ball of fire? Well that will be covered as well.

Hello! Very interesting project. I was searching for ideas to do the exact same thing, even the arduino-based control.

I was thinking…have you performed any tests on a truly vertical setup as opposed to a ramp? Also, I was trying to think of a way to make a “hot plate”. Not a burner as you may be picturing, but a peice of thick plate steel with a burner attached underneath…any thoughts?

Some of my previous designs (there have been ~5) used a vertical wood feed. I never got consistent wood flow with that type of design. The wood would get hung up, or the ash wouldn’t clear. Now that I think of it though, those versions weren’t vibrated. That may have been the problem. If that works for you please let me know!

As far as heating elements, I had toyed with the idea of making my own out of nichrome wire and embedding it in a steel plate. Just the geek cred alone was enough reason to consider it. Toaster ovens are just so easy to come by though, so I went that route. If this design didn’t work, one of the things on my “back to the drawing board” list was a custom heating element.