Constant Air + Constant Heat = Constant Smoke. Who knew?

Constant Air

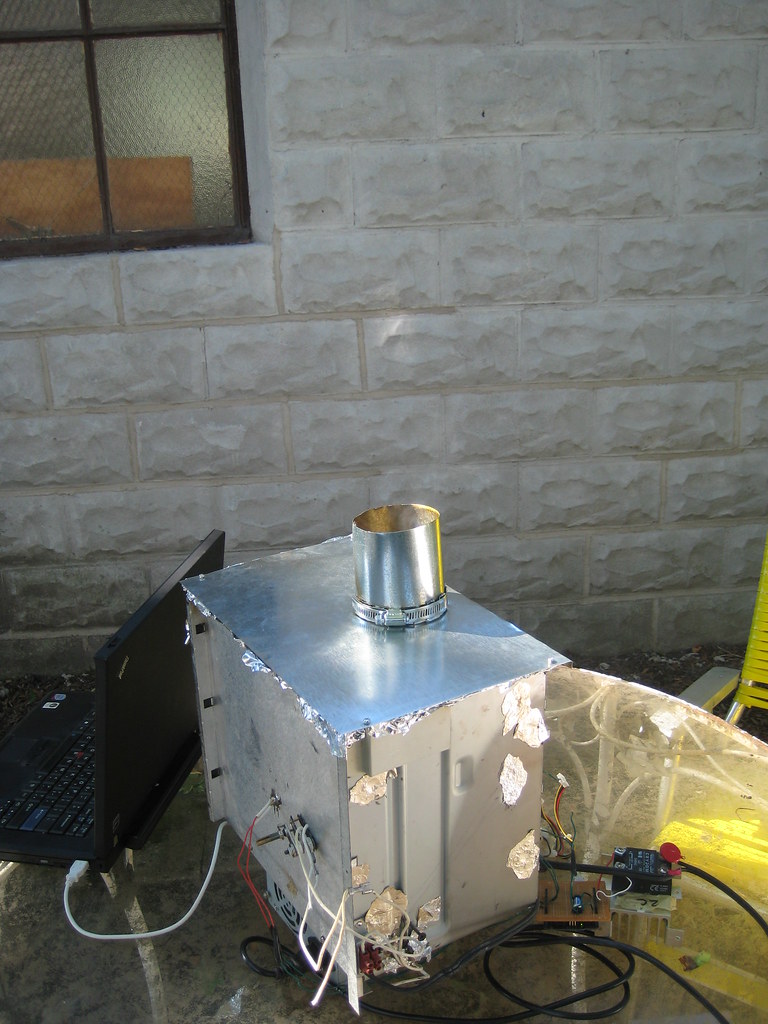

Holes. There were tons of holes. To have complete control over the air I had to patch them all. Most of them were fairly easy. A little JBWeld and aluminum foil and I had rigid, (fairly) high temp patches. All the seams got a bead of JB for good measure as well.

The biggest hole of all was at the front, where the toaster door used to be. The box was essentially open. What I did there was rotate the entire box 90 degrees, making that opening the top. The ramp needed to be repositioned, but that wasn’t too hard. Now the gaping hole was on the exit side of the chamber, where leaks aren’t as important.

The cover for this hole was also upgraded. Where before it was covered using a big piece of foil, I finally used something better: a nice metal sheet with a 3″ outlet pipe.

Constant Heat

In the previous attempt I had scrapped the stock themostat and switched to SSR control of the heating elements. I set it to a fixed value, walked away, and the whole thing promptly caught on fire.

This time around, I added a thermistor to the mix. It’s amazing what a little feedback can do. As far the control algorithm, I didn’t bother using the PID library (*gasp*.) For a process this simple all it took was a back-of-the-envelope P-only controller. It held the temperature and SSR output constant, and more importantly, things didn’t catch fire.

Vibration

As before, I used a blow-drier fan for vibration. This time, however, it was mounted on the OUTSIDE of the box. It vibrated well -10 seconds every 15 minutes- for the duration of the test. It also didn’t melt into a pile of goo, which was a definite plus.

Results

I’m ecstatic. Â All my success criteria have been met! The Smoke was consistent, and by restricting the air inlet I was able to adjust smoke density.

I put in a pound of wood (3 large chunks), and this thing ran for 5 hours straight before the smoke started to die down. There’s room for 3-4 Times as much wood in there, so an 8-16 hour run time is attainable.

Next Steps

As far as proving out the concept, I’m pretty much done. All that’s left for this phase of the project is to smoke some meat.

Beyond that I’d like to improve the design from a DIY standpoint; making it as easy to copy as possible.